KNM Barrier

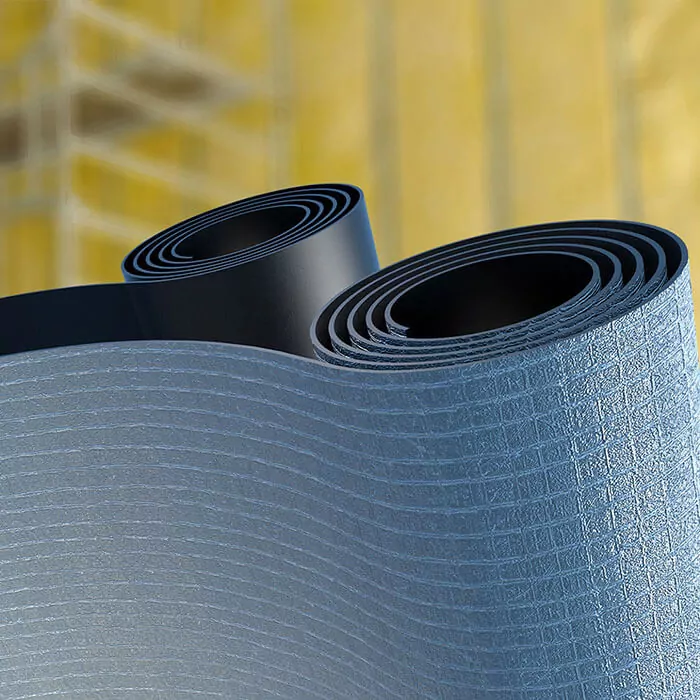

KNM Barriers are limp mass-loaded barriers available in a variety of configurations: 0.5-2 PSF densities, reinforced/non-reinforced, foil-covered, or clear. Three of the most common barriers have been tested for Class A fire performance (ASTM E84-15b) for architectural applications, which may include wrapping ductwork, pipes, or noisy equipment, or adding mass with a thin and flexible material where needed.

KNM-100B: 1 PSF non-reinforced barrier. 54″ x 60′ rolls. Class A fire rated.

KNM-100AL: 1 PSF with reinforced aluminum foil facing. 54″ x 60′ rolls. Class A.

KNM-200AL: 2 PSF with reinforced aluminum foil facing. 54″ x 30′ rolls. Class A.

What is Mass Loaded Vinyl?

KNM Barrier, or mass loaded vinyl, is a flexible sheet made from a combination of vinyl and other additives such as barium sulfate to give it mass or weight. Mass loaded vinyl’s weight may be comparable to a layer of drywall but the material is thinner and pliable.

What is mass loaded vinyl used for?

Mass loaded vinyl can be added to the buildup of walls, ceilings, or floors to add mass to the assembly, which helps block sound. Mass loaded vinyl may also be used to wrap ducts, pipes, or mechanical equipment to block sound radiating from those elements.

How is mass loaded vinyl installed as duct or pipe lagging?

For duct and pipe lagging, mass loaded vinyl with an aluminum scrim is used (KNM-100AL or KNM-200AL). Typically a layer of fiberglass or foam insulation is first installed around the pipe or duct and then the mass loaded vinyl is wrapped around with the aluminum scrim facing out. Overlapping edges of the vinyl are taped with polyscrim tape.

How is mass loaded vinyl installed in a wall or ceiling assembly?

Mass loaded vinyl is commonly installed sandwiched between layers of drywall or plywood. The material can be held in place temporary with staples until the layers of drywall are screwed through. There are a variety of ways to work with mass loaded vinyl. A project architect or acoustical engineer may have their own specific preference for installation.

How is mass loaded vinyl used in floors?

Mass loaded vinyl is sometimes installed to the joists or sandwiched between layers of plywood. It is important to note that mass loaded vinyl is not intended to have finished flooring directly adhered to it – such as tile or glue-applied finishes.

Is KNM Barrier fire rated?

KNM-100B, KNM-100AL, and KNM-200AL are all rated Class A per ASTM E54-15b.